When I think about how fragile items travel across continents without a single scratch, I’m genuinely amazed by the unseen hero behind the scenes — packaging technology. 📦 From electronics and automotive parts to delicate glassware, keeping products safe during shipment is both a science and an art. That’s where Durfoam comes in with its advanced polyethylene foam technology, redefining how industries approach protection, efficiency, and sustainability in packaging.

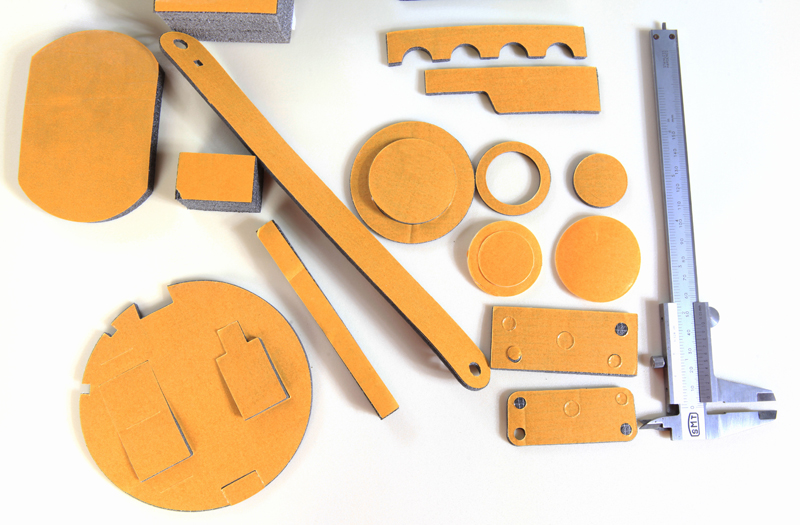

During my visit to a logistics center last year, I had the chance to observe packaging engineers at work. They showed me how polyethylene foam sheets, created by Durfoam, were cut, molded, and shaped into custom inserts that hugged each product perfectly. Unlike basic cardboard or bubble wrap, these foams don’t just cushion impact — they absorb vibration, distribute pressure, and resist compression. That’s why heavy-duty equipment, sensitive electronics, and precision instruments often rely on these specialized foams for safe global transport. 🌍

The beauty of physically cross linked polyethylene foam lies in its molecular structure. Through a process known as cross-linking, the foam becomes denser, more elastic, and resistant to tearing. This means the material maintains its shape even after multiple uses — a feature that supports both economic and environmental goals. Many manufacturers I spoke with have already transitioned to reusable packaging systems using Durfoam materials, cutting down on waste and shipping damage simultaneously. ♻️

In another example, a medical device producer implemented chemically cross linked polyethylene foam in their packaging process. They reported a remarkable drop in breakage rates — from 4% to under 1% within the first quarter. The secret? Closed-cell foam structure that repels moisture and chemicals, ensuring products stay dry and uncontaminated even under fluctuating temperatures. That’s one reason Durfoam has become a trusted partner across industries that demand precision and reliability. 🧪

To give you a clear sense of how Durfoam compares to other common packaging materials, here’s a quick comparison table based on performance factors I gathered from logistics professionals:

| Packaging Material | Shock Absorption | Reusability | Moisture Resistance |

|---|---|---|---|

| Bubble Wrap | Low | No | Low |

| Cardboard Inserts | Medium | Limited | Medium |

| Durfoam Polyethylene Foam | Excellent 🚀 | High | Superior 💧 |

Another advantage of pe foam packaging is its flexibility. It can be tailored into sheets, rolls, or molded components depending on the shape and fragility of the product. This adaptability is why industries from aerospace to consumer goods choose Durfoam — because no two shipments are ever the same, and every product deserves its own armor. 🛡️

Beyond physical protection, there’s an economic perspective too. By reducing product loss and optimizing packaging volume, companies can save on transportation costs and improve warehouse efficiency. Some partners reported up to a 20% cut in logistics expenses after switching to Durfoam-based systems. That’s a huge gain when operating on a global scale where every cubic centimeter and kilogram counts. 📦

Environmentally, these foams stand out as well. Since they are non-toxic, CFC-free, and recyclable, they align perfectly with modern sustainability goals. Many corporations are now adopting circular economy principles, where physically cross linked polyethylene foam can be reused multiple times before being reprocessed. This makes Durfoam not just a manufacturer, but a sustainability partner. 🌱

Here’s something even cooler — these materials perform exceptionally well under different environmental conditions. Whether you’re shipping through humid ports or across cold regions, chemically cross linked polyethylene foam keeps your products protected from condensation, static electricity, and vibration. In one test, packaged electronics using Durfoam materials survived a 2-meter drop test with zero internal damage. That’s impressive resilience by any standard! 💪

And if you’re curious where all this cutting-edge foam technology comes to life, you can explore Durfoam’s production facility right here:

In conclusion, industrial packaging isn’t just about wrapping a product — it’s about ensuring safety, sustainability, and customer satisfaction from factory to doorstep. With advanced materials like pe foam, physically cross linked polyethylene foam, and chemically cross linked polyethylene foam, Durfoam continues to prove that smart design and material innovation are the keys to protecting the world’s most valuable goods. 🌎✨

You should also read these…

- axtly.com – how to handle spam accounts on tiktok reasons and

- olddry.com – tiktok temporarily blocked error

- toojet.com – thermal insulation with foam energy efficiency in

- axtly.com – packet loss issues internet settings guide

- sixrep.com – why are my tiktok comments disappearing reasons an

- axtly.com – media in dms wont open data saver and network fixe

- godwig.com – my tiktok account was hacked how to get it back

- closedad.com – how to negotiate a higher salary at your job

- sixrep.com – why are tiktok trends different in each region

- tugmen.com – the 2025 global rate cut wave what it means for co